HOT PRODUCTS

Leeming est une entreprise de haute technologie intégrant la R&D, la production et la distribution, et fournit un concasseur, une fabrication de sable, des équipements de broyage, une station de concassage mobile

ore dressing ore ball mill in power plant

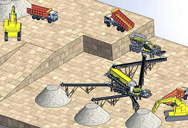

Les concasseurs à mâchoires ne fonctionnent généralement pas indépendamment, mais avec les concasseurs à cône, les concasseurs à percussion, les machines de fabrication de sable, les tamis vibrants, etc., constituent un ensemble complet de systèmes de traitement du sable et du gravier pour obtenir un traitement précis du minerai et de la roche et améliorer la pertinence du produit, Augmenter sa valeur marchande.Les lignes de production courantes sont: la ligne de production de pierre et la ligne de production de sable.

Ligne de production de pierre

Sur la base de la ligne de production de pierre, un équipement de machine de fabrication de sable pour le concassage fin et le façonnage est ajouté, ce qui permet de réaliser la production simultanée de sable et de pierre concassée fabriqués à la machine. peut répondre aux diverses exigences de traitement des clients., Pour atteindre l'objectif "d'une ligne à usages multiples", c'est un choix de ligne de production idéal pour produire des matériaux de surface d'autoroute, des agrégats de sable et de gravier de chemin de fer à grande vitesse, du sable et du gravier de la centrale hydroélectrique matériaux, terminaux portuaires et pistes aéroportuaires.

The simulation of ore-dressing plants - ScienceDirect

1984年4月1日 An efficient and automated ore-dressing plant simulator has been developed. In this simulator, stream variables can be used to describe a large number of unique solid

Click

Click

APPLIED MINERALOGY IN ORE DRESSING

Minerals are liberated by reducing the sizes of the ore pieces in stages: first to about minus 1 cm with a crusher, then to minus 10 mesh (1.65 rom) with a rod mill, and finally to free particles

Click

Click

Ball Mill - Ball Grinding Mill - SKE

The wet ball mill is the key equipment for grinding mineral after the crush process. It is mainly used in ore beneficiation plant. Output Size: 0.074-0.89mm; Milling Capacity: 1-600t/h; Learn

Click

Click

Ore Dressing Methods - 911Metallurgist

2017年4月10日 Ore-dressing methods fall naturally into two general subdivisions— (1) concentration methods and (2) direct-recovery methods (amalgamation and leaching or wet

Click

Click

The copper ore dressing plant adopts semi-autogenous grinding

2024年9月21日 The experience of designing and commissioning the grinding process combining SAG and ball milling in the copper ore dressing plant shows that the production efficiency

Click

Click

Friction and wear of liner and grinding ball in iron ore ball mill ...

2017年11月1日 To understand the friction and wear of working mediums in iron ore ball mills, experiments were conducted using the ball cratering method under dry and wet milling

Click

Click

Maximizing Efficiency in Ore Dressing: The Role of Flotation

Ball mill machines are critical for the grinding phase of ore dressing. They reduce the size of the ore particles, preparing them for further processing. Here’s how they contribute to the...

Click

Click

Ball Mill Design/Power Calculation - 911Metallurgist

2015年6月19日 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill

Click

Click

Common Basic Formulas for Mineral Processing

2016年3月21日 Pulp Densities. Pulp densities indicate by means of a tabulation the percentages of solids (or liquid-to-solid ratio) in a sample of pulp. This figure is valuable in two ways—directly, because for each unit process and operation in

Click

Click

Inventory Of Common Faults And Solutions Of Mining

2024年10月25日 Reason: This is a common problem mining ball mills face, resulting in low productivity and low ore processing efficiency. One reason may be the improper design of the grinding chamber, which affects the flow of

Click

Click

Ball mill - Wikipedia

A section cut-through of ball mills. A ball mill is a type of grinder filled with grinding balls, used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering.It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell.

Click

Click

Mineral Processing and Ore Dressing - 911Metallurgist

2016年6月2日 Before the event of ore dressing, crude ores were shipped directly to the smelters, ... This has been accomplished through the use of a jig and/or a unit flotation cell in the ball mill-classifier circuit. ... In past years it has been a common yard stick to assume that a cyanide plant must handle at least 100 tons per day to be ...

Click

Click

News - Iron ore mineral processing with standing grinding or ball ...

Iron ore dry grinding dry magnetic process of iron ore dressing mill for dry fine grinding, grinding fine reading can guarantee-200 above 80%, equivalent to the common process of ball mill and screw grading machine or ball mill and cyclone grinding closed process, at the same time, iron ore dressing mill processing capacity is much higher than the ball mill, low energy

Click

Click

LECTURE NOTES ON Mineral Processing. (3rd Semester

subsequent operations will be termed as Ore Dressing or Mineral Beneficiation. So mineral dressing or ore dressing is commonly regarded as processing of raw ores to yield marketable products by such physical means those do not destroy the physical and chemical identity of the ore. Economic Justification of Mineral Dressing: 1.

Click

Click

Ball Mills - 911Metallurgist

2017年2月13日 In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rod mill or ball mill, the ore in order to liberate the minerals. In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment.

Click

Click

How To Choose Ball mill Or Wet Pan Mill In Grinding Gold

2024年10月25日 Dry or wet grinding of various ores and other grindable materials. The processed materials include gold, iron ore, copper ore, molybdenum ore, manganese, lithium ore, antimony ore, and other minerals, with a wide range of applications. Its core function is to grind materials. Ball mills are key grinding equipment for processing materials after ...

Click

Click

Ball Mill Is The Key To Grinding Lithium Ore - JXSC Machinery

2024年10月25日 Additionally, the ball mill’s versatility allows parameters such as speed, feed rate and material composition to be adjusted, making it adaptable to different types of lithium ore. This flexibility is essential to optimize the grinding process for each specific ore type, thereby increasing cost efficiency and resource sustainability.

Click

Click

Common Basic Formulas for Mineral Processing

2016年3月21日 Pulp Densities. Pulp densities indicate by means of a tabulation the percentages of solids (or liquid-to-solid ratio) in a sample of pulp. This figure is valuable in two ways—directly, because for each unit process and operation in

Click

Click

Ball Mills - 911Metallurgist

2017年2月13日 In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rod mill or ball mill, the ore in order to liberate the

Click

Click

Lithium Ore Flotation Plant - Pineer Mining Machinery

Ball Mill Machine; Wet Pan Mill For Gold; Hydrocyclone; Double-impellers leaching tank; Flotation cells; Project Gallery; Mining Blogs; Contact Us; for: Home; ... Lithium Ore Flotation Plant; COLTAN/TANTALITE ORE

Click

Click

Iron Ore Processing: From Extraction to Manufacturing

2024年4月26日 Home Blogs Dressing Iron Ore Processing: From Extraction to ... Overflow Type Ball Mill; Details Quotation. Magnetic Separator; Details Quotation. Efficient Thickener; RELATED POSTS. Sheena Oct 26, 2024. Chrome Ore Beneficiation Plant Investment Advice read more. Sheena Oct 24, 2024. The Guide to Nickel Processing Methods read more ...

Click

Click

Equipment Configuration Plan and Process of Iron Ore Dressing Plant ...

3. Separation stage. The separation stage is the core link of the iron ore beneficiation plant. We select suitable magnetic separation equipment according to the magnetic characteristics of the ore.

Click

Click

Small Mineral Processing Plant Design - 911Metallurgist

2016年5月12日 Flowsheet No. 3 is flexible enough to handle most types of ore dressing problems. It permits gravity concentration, ... This Portable Mill was designed for use at a mine in Bolivia and utilizes a Diesel Power Plant with belt drives. ... 1—Belt Ore Feeder 1—30″x 18″ Ball Mill 1—Spiral Screen 1—4″x 6″ Selective Mineral Jig

Click

Click

Wet Overflow Type Ball Mill and Applications

2024年1月12日 How Overflow Type Ball Mill Works. Material Feed: The raw material is fed into the mill at one end and travels through the mill by rotation. The feed enters the mill at a specific rate, ensuring a controlled grinding process.; Grinding Process: As the mill rotates, the grinding media crushes and grinds the material into a fine powder. The wet conditions enhance the

Click

Click

Lead-zinc Ore Dressing Plant Improvement - JXSC Mineral

2023年1月31日 There are many problems of old lead-zinc ore dressing plant, we improve the plant and equipment, make it more efficient. Skip to content. JXSC Mineral. Home; ... 1 set of MQG2100 x 3000 ball mill and 1 set of FG-15 ... Large suction volume and low power consumption. Each tank has triple the functions of air suction, slurry suction, ...

Click

Click

Lead and Zinc ore dressing - ZJH minerals

Sulfide ores are usually flotation method.Oxidized ore is beneficiated by flotation or gravity separation combined with flotation, or flotation after curing roasting, or flotation after gravity separation with sulfuric acid treatment.For lead and zinc ore containing polymetallic, magnetic – flotation, gravity-flotation, gravity-magnetic – flotation and other combined beneficiation

Click

Click

Ball Mill In Cement Plant - Selling Various Types Of Cement Mill

85tph Cement Ball Mill In Indian Cement Plant; Ore Dressing Line; ... and the power of the motor, etc. Different Ball Mill models can be customized according to different production needs. In the cement production process, Ball Mill is usually used in conjunction with other equipment, such as crushers, ...

Click

Click<< Previous : Broyage De Messages De Sable

>> Next : Penera Vibratoria Para Areia