HOT PRODUCTS

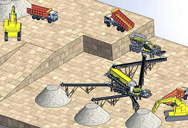

Leeming est une entreprise de haute technologie intégrant la R&D, la production et la distribution, et fournit un concasseur, une fabrication de sable, des équipements de broyage, une station de concassage mobile

sintering process of iron ore

Les concasseurs à mâchoires ne fonctionnent généralement pas indépendamment, mais avec les concasseurs à cône, les concasseurs à percussion, les machines de fabrication de sable, les tamis vibrants, etc., constituent un ensemble complet de systèmes de traitement du sable et du gravier pour obtenir un traitement précis du minerai et de la roche et améliorer la pertinence du produit, Augmenter sa valeur marchande.Les lignes de production courantes sont: la ligne de production de pierre et la ligne de production de sable.

Ligne de production de pierre

Sur la base de la ligne de production de pierre, un équipement de machine de fabrication de sable pour le concassage fin et le façonnage est ajouté, ce qui permet de réaliser la production simultanée de sable et de pierre concassée fabriqués à la machine. peut répondre aux diverses exigences de traitement des clients., Pour atteindre l'objectif "d'une ligne à usages multiples", c'est un choix de ligne de production idéal pour produire des matériaux de surface d'autoroute, des agrégats de sable et de gravier de chemin de fer à grande vitesse, du sable et du gravier de la centrale hydroélectrique matériaux, terminaux portuaires et pistes aéroportuaires.

(PDF) Iron Ore Sintering: Process - ResearchGate

2017年2月16日 Sintering is a thermal agglomeration process that is applied to a mixture of iron ore fines, recycled ironmaking products, fluxes, slag-forming

Click

Click

Iron ore sintering - ScienceDirect

2015年1月1日 Sintering is the most economic and widely used agglomeration process to prepare iron ore fines for blast furnace use. In this chapter, the sintering process is first

Click

Click

Sintering: A Step Between Mining Iron Ore and

2019年6月11日 Sinter is the primary feed material for making iron and steel in a blast furnace. According to the U.S. Environmental Protection Agency, the sintering process converts fine-sized raw materials, including iron ore, coke

Click

Click

Thermodynamic Analysis of Iron Ore Sintering Process

2020年11月16日 The sinter process of iron ore with biomass carbon instead of coke breeze as fuel was investigated via thermodynamic analysis in this paper through a comparison of sinter composition indexes, metallurgical properties,

Click

Click

Application of deep learning in iron ore sintering process: a review ...

2024年3月16日 The production of blast furnace ironmaking depends on large part on the sintering of iron ore; thus, it is crucial to model, simulate, and optimise the sintering

Click

Click

Ore Sintering - an overview ScienceDirect Topics

Sintering is the most economic and widely used agglomeration process to prepare iron ore fines for blast furnace use. Compared with pellets, production of sinter is cheaper, and compared

Click

Click

Iron Ore Sintering - SpringerLink

2023年6月8日 Iron ore sintering is the iron ore powder agglomeration process that changes fine iron ore powder into the lumpy iron-bearing raw material used for blast furnace

Click

Click

Iron Ore Sintering: Raw Materials and Granulation: Mineral

2016年11月14日 Sintering is an agglomeration process that fuses iron ore fines, fluxes, recycled products, slag-forming elements and coke. The purpose of sintering is to obtain a

Click

Click

Iron Ore Sintering: Process - Semantic Scholar

Iron ore sintering is a pretreatment step of smelting that agglomerates the iron ore using surface melting of green pellets to improve the quality of the steel product. The sintering

Click

Click

Iron ore sintering - ScienceDirect

2022年1月1日 The sintering process begins with preparation of a sinter mixture consisting of iron ore fines, fluxes, solid fuel (called bonding agents in Japan) such as coke breeze, and return fines from the sinter plant as well as recycled ferruginous materials from downstream iron and steelmaking processes.

Click

Click

Iron ore sintering. Part 1. Theory and practice of the

2013年8月1日 Sintering is a process by which a mixture of iron ores, fl uxes and coke is agglomerated in a sinter plant to manufacture a sinter product of a suitable composition, quality and granulometry to be ...

Click

Click

Optimal proportioning of iron ore in sintering process based on ...

2024年3月6日 Proportioning is an important part of sintering, as it affects the cost of sintering and the quality of sintered ore. To address the problems posed by the complex raw material information and numerous constraints in the sintering process, a multi-objective optimisation model for sintering proportioning was established, which takes the proportioning cost and TFe

Click

Click

Combustion mechanism of benzene in iron ore sintering process ...

2023年7月20日 The iron ore sintering process is the main source of VOCs emission in the iron and steel industry, and its VOCs emission accounts for about 69.6% . The organic compounds in the solid fuel and the oil components from the raw materials such as rolling oily sludge are pyrolyzed in the preheating layer ...

Click

Click

Thermodynamic Analysis of Iron Ore Sintering Process Based on

2020年11月16日 The sinter process of iron ore with biomass carbon instead of coke breeze as fuel was investigated via thermodynamic analysis in this paper through a comparison of sinter composition indexes, metallurgical properties, and pollutant emissions. Straw charcoal was used in this paper, and its replacement does not adversely affect the composition index of iron ore,

Click

Click

Disposal of zinc extraction residues via iron ore sintering process

2023年11月6日 Thus, the iron ore sintering process provided a viable solution for resource utilization and environmentally friendly treatment of zinc extraction residues. Zinc extraction residue, a solid waste generated from the treatment of zinc-containing dust in rotary kilns, is commonly stockpiled in steel companies for

Click

Click

Numerical Modeling of the Iron Ore Sintering Process

2012年9月14日 Iron ore sintering involves the movement of a flame front down a particulate bed, and a series of physico-chemical reactions over a large temperature range.

Click

Click

Multi-objective Optimization of Integrated Iron Ore Sintering Process ...

2020年3月20日 In the iron ore sintering process, it is desirable to maximize the productivity and quality of sinter while minimizing the fuel consumption for any given raw material (iron ore, flux and solid fuel) quality. However, given the complexity of the sintering process and the large number of manipulated variables, it is not practical for operators to identify appropriate set

Click

Click

Ore Sintering - an overview ScienceDirect Topics

Iron ore sintering involves flows, heat transfer, species transport, and phase changes in reactive porous media coupled with solid phase and gaseous phase reactions. In the past 40 years, numerous mathematical models have been developed to describe the iron ore sintering process [10, 65–77].

Click

Click

Basics of Iron Ore Sintering SpringerLink

2023年10月15日 In case of chromite, the temperature required for sintering is about 200 0 C more than that required for iron ore sintering. The process conditions for manganese ore sintering are almost similar to that for iron ore. The author has actively contributed to projects for setting up of batch type (capacity 15000 tpa) sinter plants at industry site.

Click

Click

Prediction of sinter yield and strength in iron ore sintering process ...

2018年2月25日 The iron ore sintering process was simulated and computational domain was the same as the configuration of a sinter pot as shown in Fig. 1. Entrance of the sinter pot was defined as a velocity inlet. The magnitude of velocity

Click

Click

Effect of bed shrinkage on iron ore sintering process

2022年6月13日 Iron ore sintering entails high energy consumption and also produces significant pollution, responsible for the highest share of CO 2 emission, as well as SO 2 and NOx emissions, in the iron and steel production processes. 5 The SO 2 and NO X emissions from this process account for ∼70% and ∼40% of the total iron and steel industry emissions,

Click

Click

A Novel Sintering Process for Porous Iron Ore Sintering with

2022年2月28日 The present work proposes a novel process to sinter porous iron ore (porosity ~23–24%) with enhanced productivity and quality. The iron ore is pre-processed in the presence of calcined lime for the temporary closure of pores, which further prevents water absorption during the granulation process in drum in the presence of water. The calcined lime coated iron ore

Click

Click

Effects of Particle Size of Coke on Iron Ore Sintering Process

2019年2月13日 Coke breeze is the main heat source in sintering process. Its combustion yields enough amounts of heat which melts the sinter mix. One of the factors that significantly affect the course of coke breeze combustion is its grain size [1,2,3].It is known that fine-grained coke reduces permeability of the sinter mix and the use of coke breeze with particle size below

Click

Click

Reductants in iron ore sintering: A critical review - ScienceDirect

2023年1月15日 Moreover, the conventional iron making unit, i.e. blast furnace requires the raw material in the form of iron oxide with a size range of 10–120 mm. Sintering is the oldest agglomerate thermal process using iron ore mineral fines of 0.5–8 mm, along with the reductant, fluxes, and other byproducts of the iron and steel industry operated around a temperature of

Click

Click

Modeling and Simulation of Iron Ore Sintering Process with ...

version of the iron ore sintering process in sinter pot. In recent decades, numerical simulation, as an effective theoretical method complementary to laboratory investiga-tion, is being increasingly applied to analyze iron ore sinter-ing. Various mathematical models of iron ore sintering have been developed.2–5) It has been proved useful in ...

Click

Click

(PDF) Iron Ore Sintering: Quality Indices - ResearchGate

2017年5月2日 Sinter plants process a mixture of iron ore fines, recycled ironmaking products, ... F. Verdeja (2017) Iron Ore Sintering: Quality Indices, Mineral Processing and Extractive Metallurgy.

Click

Click

Iron Ore Sintering Process: Transforming Raw Ore into High

2024年3月20日 Iron Ore Sintering Process. Sintering burden mix on the grate of an agglomeration machine with air suction through the burden layer is the most common agglomeration method. Sinter burden includes: iron-containing materials (concentrate, ore, flue dust) – 40 – 50%;

Click

Click

Enhanced Removal of Potassium, Sodium, and Lead During the Iron Ore

2024年5月9日 To alleviate the strain on the extensive demand for iron sources, reduce the cost, and transition towards greener metallurgy, iron-bearing wastes like blast furnace dust and sinter dust, along with alkali metal-rich or lead-rich iron ores, are recycled through the iron ore sintering process [1,2,3,4,5].This practice, however, elevates the concentration of undesired

Click

Click

Iron Ore Sintering: Raw Materials and Granulation

2016年10月28日 Sintering is an agglomeration process that fuses iron ore fines, fluxes, recycled products, slag-forming elements and coke. The purpose of sintering is to obtain a product with suitable ...

Click

Click<< Previous : Concasseur à Pierre Machines Petit Rocher De Concassage