HOT PRODUCTS

Leeming est une entreprise de haute technologie intégrant la R&D, la production et la distribution, et fournit un concasseur, une fabrication de sable, des équipements de broyage, une station de concassage mobile

dressing of the copper ore

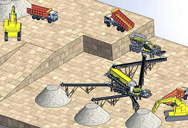

Les concasseurs à mâchoires ne fonctionnent généralement pas indépendamment, mais avec les concasseurs à cône, les concasseurs à percussion, les machines de fabrication de sable, les tamis vibrants, etc., constituent un ensemble complet de systèmes de traitement du sable et du gravier pour obtenir un traitement précis du minerai et de la roche et améliorer la pertinence du produit, Augmenter sa valeur marchande.Les lignes de production courantes sont: la ligne de production de pierre et la ligne de production de sable.

Ligne de production de pierre

Sur la base de la ligne de production de pierre, un équipement de machine de fabrication de sable pour le concassage fin et le façonnage est ajouté, ce qui permet de réaliser la production simultanée de sable et de pierre concassée fabriqués à la machine. peut répondre aux diverses exigences de traitement des clients., Pour atteindre l'objectif "d'une ligne à usages multiples", c'est un choix de ligne de production idéal pour produire des matériaux de surface d'autoroute, des agrégats de sable et de gravier de chemin de fer à grande vitesse, du sable et du gravier de la centrale hydroélectrique matériaux, terminaux portuaires et pistes aéroportuaires.

(PDF) A Method of Ore Blending Based on the Quality

2021年5月31日 Qualified ore dressing products can make the ore dressing more smoothly. The existing ore blending modeling usually only considers the quality of ore blending products and ignores the...

Click

Click

Copper processing - Ores, Refining, Smelting Britannica

In the ore-dressing plant, the material received from the mine is crushed in several stages and finely ground to a size which ensures that copper minerals are liberated from the waste materials, or gangue.

Click

Click

Ore Dressing Methods - 911Metallurgist

2017年4月10日 Ore-dressing methods fall naturally into two general subdivisions— (1) concentration methods and (2) direct-recovery methods (amalgamation and leaching or wet

Click

Click

Mineral Processing, Separation Beneficiation

flotation, in mineral processing, method used to separate and concentrate ores by altering their surfaces to a hydrophobic or hydrophilic condition—that is, the surfaces are either repelled or attracted by water.

Click

Click

[PDF] Ore Dressing: Principles and Practice - Semantic Scholar

Materials Science. TEXT-BOOKS of ore dressing are frequently little more than extracts from makers' catalogues. The volume by Prof. Simons is of a different character. It gives the usual

Click

Click

Comprehensive Guide to Copper Ore Processing

Common copper ore dressing technologies include: flotation, gravity separation, leaching and combined dressing. Efficient dressing equipment is another important factor in improving

Click

Click

Discussion on the Innovation of Copper Ore Dressing Technology

6 天之前 The continuous progress of copper ore dressing technology has provided mining companies with a practical solution to improve resource utilization, reduce costs and reduce

Click

Click

Introduction of Copper Ore Dressing Process - Xinhai

2018年5月2日 Current copper ore dressing process includes following stages: firstly, crush the raw ore to a certain size with crushing and grinding equipment, then useful minerals realize full

Click

Click

Experimental study on ore dressing of the D. R. Congo low grade

2019年12月9日 Black copper, red copper and ferromanganese heterophase (containing copper) are the main copper ores. The flotation experiment results of typical low-grade copper

Click

Click

Copper (Cu) Ore Minerals, Occurrence » Geology

2023年4月23日 Copper (Cu) ore is a naturally occurring mineral deposit that contains copper in varying concentrations. It is an important industrial metal that has been used by human civilizations for thousands of years due to its

Click

Click

Zambia’s Copper Oxide Ore Dressing – Case Study

2024年5月21日 Among these, copper primarily existed in the form of copper oxide, adding complexity to the copper ore dressing process. Facing the intricate ore dressing conditions, the Dasen Mining team, leveraging their rich

Click

Click

(PDF) Overview of Mineral Processing Methods

2015年8月3日 The first process that most of the ores or minerals undergo after they leave any mine, is mineral processing or mineral/ ore dressing. It is a process of ore preparation, milling, and ore dressing ...

Click

Click

Mineral dressing (= Orebeneficiation) - جامعة الملك عبد ...

Mineral dressing (= Orebeneficiation) The first process most ores undergo after they leave the mine is mineral dressing (processing), also called ore preparation, milling, and ore dressing or ore beneficiation. Ore dressing is a process of mechanically separating the grains of ore minerals from the gangue minerals, to produce a concentrate ...

Click

Click

Sustainable Use of Copper Resources: Beneficiation of Low-Grade Copper Ores

2022年4月27日 copper ore can float better in the sequence of BBT > DBD > SIBX. It was explained as due. to the highest negative zeta potential (ZP) value observed in BBT for copper sulphides,

Click

Click

POTENTIAL ENHANCEMENT OF COMPREHENSIVE COPPER–MOLYBDENUM ORE DRESSING ...

The copper concentrate has the following phase composition, % (relative): 1.48 oxi dized; 25.35 secondary; 70.28 primary; 2.89 gray copper ore; 100 total. The comparison of data from Tables 2 and 3 yields that the incremental content of copper in the copper concentrate is achieved owing to primary copper minerals. Molybdenum concentrate.

Click

Click

Mineral Processing and Ore Dressing - 911Metallurgist

2016年6月2日 Before the event of ore dressing, crude ores were shipped directly to the smelters, or the refineries, with the shipper paying the freight and treatment. ... lead, zinc, and iron. Lead and copper are rather close together but

Click

Click

Copper Ore Processing Plants, Flow And Equipment

2024年10月25日 Copper industrial minerals include: natural copper, chalcopyrite, chalcocite, tetrahedrite, azurite, malachite, etc. Chalcopyrite (a compound of copper, sulfur, and iron) is mined mainly, followed by chalcocite and bornite. If copper ore wants to be fully utilized, it must be processed by flotation. Flotation separation is an important copper ore beneficiation

Click

Click

The Utilization Research of High Efficient Collector BK404 on the ...

The Utilization Research of High Efficient Collector BK404 on the Copper Sulfide Ore Dressing @inproceedings{Yuehua2014TheUR, title={The Utilization Research of High Efficient Collector BK404 on the Copper Sulfide Ore Dressing}, author={Ye Yue-hua and Liang Guangquan and Xiao Xiwen}, year= {2014 ...

Click

Click

Introduction of Copper Ore Dressing Process - Xinhai

2018年5月2日 Current copper ore dressing process includes following stages: firstly, crush the raw ore to a certain size with crushing and grinding equipment, then useful minerals realize full monomer dissociation; Secondly, use certain copper ore dressing process and copper processing equipment to isolate useful minerals according to ore properties.

Click

Click

Introduction of Copper Ore Dressing Process - Xinhai

2018年5月2日 Current copper ore dressing process includes following stages: firstly, crush the raw ore to a certain size with crushing and grinding equipment, then useful minerals realize full monomer dissociation; Secondly, use certain copper ore dressing process and copper processing equipment to isolate useful minerals according to ore properties.

Click

Click

Discussion on the Innovation of Copper Ore Dressing Technology

6 天之前 01 Traditional copper ore dressing methods and existing problems. 1. Gravity separation method. Gravity separation method mainly achieves separation through the difference in specific gravity between copper ore and waste rock. However, the gravity separation method has the problem of low processing capacity and poor recovery effect on fine-grained copper ore.

Click

Click

Mineral Processing and Ore Dressing - 911Metallurgist

2016年6月2日 Before the event of ore dressing, crude ores were shipped directly to the smelters, or the refineries, with the shipper paying the freight and treatment. ... lead, zinc, and iron. Lead and copper are rather close together

Click

Click

Iron ore mining and dressing - tec-science

2018年6月21日 Ore processing (or ore dressing) is the separation of iron ore from gangue in order to optimize the blast furnace process! In principle, the undesirable gangue can never be completely separated from the iron ores during ore dressing. This means that a certain amount of unwanted elements always enters the blast furnace process.

Click

Click

Recent Advances in Copper Ore Processing and Extraction

2022年1月28日 The copper ore in Chilean copper porphyry deposits is often associated with molybdenum minerals. This copper–molybdenum (Cu–Mo) sulfide ore is generally mined from various locations in the mining site; thus, the mineral composition, oxidation degree, mineral particle size, and grade vary.

Click

Click

These Copper Oxide Ore Beneficiation Methods Greatly Recovery

2024年10月18日 Advances in copper oxide ore beneficiation methods have significantly improved recovery efficiency, paving the way for more sustainable mining practices. Each method offers unique advantages based on specific ore characteristics. The integration of its flotation technology can not only improve resource utilization, but also improve the cost-effectiveness

Click

Click

LECTURE NOTES ON Mineral Processing. (3rd Semester

So mineral dressing or ore dressing is commonly regarded as processing of raw ores to yield marketable products by such physical means those do not destroy the physical and chemical identity of the ore. Economic Justification of Mineral Dressing: 1. To purify and upgrade the ore:

Click

Click

The fate of molybdenum in the residues of a Chilean copper ore ...

2022年6月15日 Besides the copper ore, pyrite was used as fuel and garnet skarn as well as carbonate rocks as flux. The Cu content of the matte was about 45 % at a monthly production rate of about 400–500 tons. During the early smelting activities, high quality slags were exported to Wales for further processing in exchange for Welsh coal ( Rees Jones, 2016 ).

Click

Click

Flotation Mineral Processing, Separation Beneficiation

Flotation, in mineral processing, method used to separate and concentrate ores by altering their surfaces to a hydrophobic or hydrophilic condition—that is, the surfaces are either repelled or attracted by water. The flotation process was developed on a

Click

Click

The Utilization Research of High Efficient Collector BK404 on the ...

The Utilization Research of High Efficient Collector BK404 on the Copper Sulfide Ore Dressing @inproceedings{Yuehua2014TheUR, title={The Utilization Research of High Efficient Collector BK404 on the Copper Sulfide Ore Dressing}, author={Ye Yue-hua and Liang Guangquan and Xiao Xiwen}, year= {2014 ...

Click

Click